BioDent Calculations

BioDent calculates 9 parameters automatically:

- 1st Cycle Indentation Distance (1st ID)

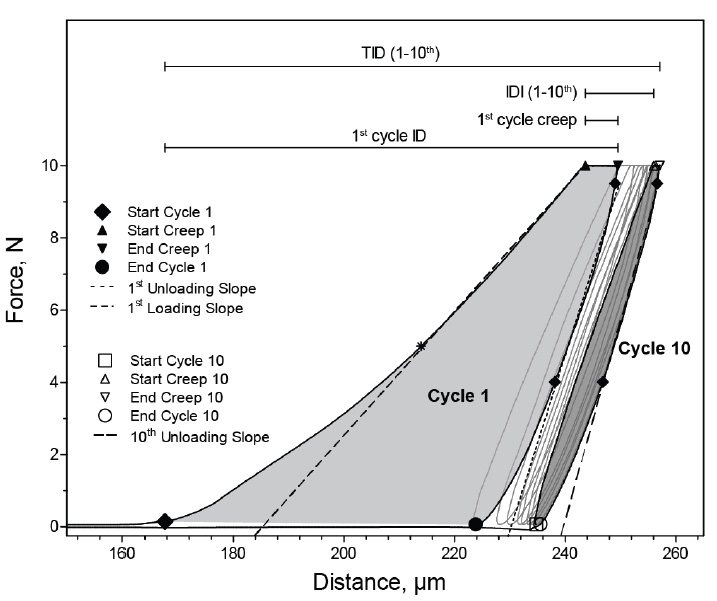

- Total Indentation Distance (TID)

- 1st Cycle Creep Indentation Distance (1st CID)

- Indentation Distance Increase (IDI)

- Average Creep Indentation Distance (Avg CID)

- 1st Cycle Unloading Slope (1st US)

- Average Unloading Slope (Avg. US)

- Average Loading Slope (Avg. LS)

- Average Energy Dissipated (Avg. ED)

Distance Based Parameters

1st Cycle Indentation Distance (1st ID)

The first cycle of any RPI measurement creates a localized plastic deformation. The depth of this initial plastic deformation is directly related to hardness, which will have a high correlation to density and tissue mineralization. This is referred to as the 1st Cycle Indentation Distance. 80~90% of the total indentation distance (TID) is achieved in the first cycle of testing.

- Gallant, M. A., D. M. Brown, J. M. Organ, M. R. Allen and D. B. Burr (2013). "Reference-point indentation correlates with bone toughness assessed using whole-bone traditional mechanical testing." Bone 53(1): 301-305.

- Granke, M., A. J. Makowski, S. Uppuganti, M. D. Does and J. S. Nyman (2015). "Identifying novel clinical surrogates to assess human bone fracture toughness." Journal of Bone and Mineral Research: n/a-n/a.

- Beutel, B. G. and O. D. Kennedy (2015). "Characterization of damage mechanisms associated with reference point indentation in human bone." Bone 75(0): 1-7.

Total Indentation Distance (TID)

During a RPI measurement, multiple indentations can be made in the same location. The total depth achieved by the Test Probe after all the indentations are complete is called the Total Indentation Distance (TID). TID has been inversely correlated with toughness in many cases but not all. TID is not a direct measure to calculate toughness but is an expression of bone quality. TID can directly assess the ability of the bone matrix to resist crack initiation and propagation.

- Carriero, A., J. L. Bruse, K. J. Oldknow, J. L. Millán, C. Farquharson and S. J. Shefelbine (2014). "Reference point indentation is not indicative of whole mouse bone measures of stress intensity fracture toughness." Bone 69(0): 174-179.

- Katsamenis, O. L., T. Jenkins and P. J. Thurner (2015). "Toughness and damage susceptibility in human cortical bone is proportional to mechanical inhomogeneity at the osteonal-level." Bone(0)

1st Cycle Creep Indentation Distance (1st CID)

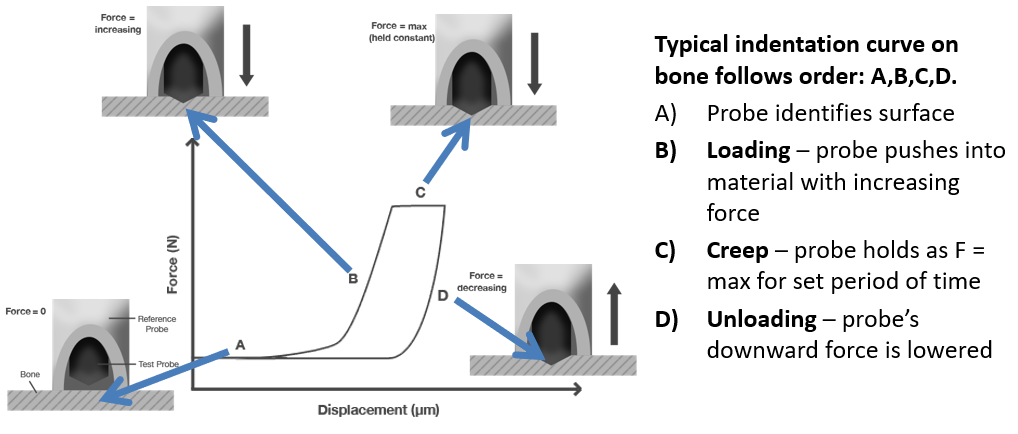

Creep is defined as the tendency of a material after being subjected to high levels of stress, e.g. high temperatures, to change its form in relation to time. During each indentation, the Test Probe holds a constant, maximum force for 1/3 of the indentation. There are three stages of creep: Primary, Steady, and Tertiary. Since Reference Point Indentation interacts with the material at a relatively high rate, or short duration, all of the Creep is considered to be in the Primary and Steady states. The ability of bone material to resist constant pressure (1st CID) has been inversely correlated to crack growth toughness and damage susceptibility.

- Katsamenis, O. L., T. Jenkins and P. J. Thurner (2015). "Toughness and damage susceptibility in human cortical bone is proportional to mechanical inhomogeneity at the osteonal-level." Bone(0).

Indentation Distance Increase (IDI)

Indentation Distance Increase (IDI) is a unique parameter found only with Reference Point Indentation. IDI is inversely correlated with toughness and fracture. It has been found to be inversely proportional to crack growth toughness, resistance to fracture, extrinsic strength and energy to failure. However, it is not simply hardness but also reflects bone brittleness, i.e., its propensity to absorb energy before fracture. IDI is representing therefore a local measure of the post- yield mechanical properties of the bone.

Evidence

- Nyman, J. S. and A. J. Makowski (2012). "The Contribution of the Extracellular Matrix to the Fracture Resistance of Bone." Current osteoporosis reports 10(2): 169-177.

- Diez‐Perez, A., R. Güerri, X. Nogues, E. Cáceres, M. J. Peña, L. Mellibovsky, C. Randall, D. Bridges, J. C. Weaver and A. Proctor (2010). "Microindentation for in vivo measurement of bone tissue mechanical properties in humans." Journal of Bone and Mineral Research 25(8): 1877-1885.

- Güerri‐Fernández, R. C., X. Nogués, J. M. Quesada Gómez, E. Torres del Pliego, L. Puig, N. García‐Giralt, G. Yoskovitz, L. Mellibovsky, P. K. Hansma and A. Díez‐Pérez (2013). "Microindentation for in vivo measurement of bone tissue material properties in atypical femoral fracture patients and controls." Journal of Bone and Mineral Research 28(1): 162-168.

- Gallant, M. A., D. M. Brown, J. M. Organ, M. R. Allen and D. B. Burr (2013). "Reference-point indentation correlates with bone toughness assessed using whole-bone traditional mechanical testing." Bone 53(1): 301-305.

- Setters, A. and I. Jasiuk (2014). "Towards a standardized reference point indentation testing procedure." Journal of the Mechanical Behavior of Biomedical Materials 34(0): 57-65.

- Granke, M., A. Coulmier, S. Uppuganti, J. A. Gaddy, M. D. Does and J. S. Nyman (2014). "Insights into Reference Point Indentation Involving Human Cortical Bone: Sensitivity to Tissue Anisotropy and Mechanical Behavior." Journal of the Mechanical Behavior of Biomedical Materials.

- Carriero, A., J. L. Bruse, K. J. Oldknow, J. L. Millán, C. Farquharson and S. J. Shefelbine (2014). "Reference point indentation is not indicative of whole mouse bone measures of stress intensity fracture toughness." Bone 69(0): 174-179.

- Hoffseth, K., C. Randall, P. Hansma and H. T. Y. Yang (2015). "Study of indentation of a sample equine bone using finite element simulation and single cycle reference point

- Beutel, B. G. and O. D. Kennedy (2015). "Characterization of damage mechanisms associated with reference point indentation in human bone." Bone 75(0): 1-7.

- Katsamenis, O. L., T. Jenkins and P. J. Thurner (2015). "Toughness and damage susceptibility in human cortical bone is proportional to mechanical inhomogeneity at the osteonal-level." Bone(0)

Average Creep Indentation Distance (Avg. CID)

RPI offers a unique capability to assess changes in material properties of the same local material within the same measurement. In most cases, the 1st Cycle Creep Indentation Distance is larger than iterative cycles. By calculating the Avg. CID, the local tissue resistance to fatigue, or compressibility, can be measured. After an initial indentation, a material will be compressed after the initial plastic deformation. If the Avg. CID approaches the 1st CID value, the material can be considered to be highly plastic, like fresh snow. This has to do with more than just the mechanical properties of the material it also has to do with the local microstructure. For example, freshly packed snow or foam can sustain repetitive compression. Eventually, most materials will prevent repetitive compression. For bone, an equivalent Avg. CID and 1st CID would imply a consistent failure at a constant force; very weak bone.

- Setters, A. and I. Jasiuk (2014). "Towards a standardized reference point indentation testing procedure." Journal of the Mechanical Behavior of Biomedical Materials 34(0): 57-65.

- Carriero, A., J. L. Bruse, K. J. Oldknow, J. L. Millán, C. Farquharson and S. J. Shefelbine (2014). "Reference point indentation is not indicative of whole mouse bone measures of stress intensity fracture toughness." Bone 69(0): 174-179.

Stiffness Parameters

1st Cycle Unloading Slope

Traditional indentation protocols use the unloading slope to calculate Elastic Modulus. For RPI, the only viable output parameter is an indicator of material Stiffness, which is measured as the top portion of the 1st cycle unloading slope; after the 1st cycle plastic deformation. It can be considered a surrogate for the bone matrix modulus.

- Gallant, M. A., D. M. Brown, J. M. Organ, M. R. Allen and D. B. Burr (2013). "Reference-point indentation correlates with bone toughness assessed using whole-bone traditional mechanical testing." Bone 53(1): 301-305.

- Granke, M., A. Coulmier, S. Uppuganti, J. A. Gaddy, M. D. Does and J. S. Nyman (2014). "Insights into Reference Point Indentation Involving Human Cortical Bone: Sensitivity to Tissue Anisotropy and Mechanical Behavior." Journal of the Mechanical Behavior of Biomedical Materials.

- Carriero, A., J. L. Bruse, K. J. Oldknow, J. L. Millán, C. Farquharson and S. J. Shefelbine (2014). "Reference point indentation is not indicative of whole mouse bone measures of stress intensity fracture toughness." Bone 69(0): 174-179.

Average Unloading Slope

Like Avg. CID, Avg. Unloading Slope is an indication of how much the material changes upon iterative cycles. Typically, materials will become more stiff (increasing unloading slope) over iterative indentations. In clinical settings, Avg US discriminates between bones with diseases that cause a change of matrix stiffness vs those which may affect bone toughness.

- Granke, M., A. Coulmier, S. Uppuganti, J. A. Gaddy, M. D. Does and J. S. Nyman (2014). "Insights into Reference Point Indentation Involving Human Cortical Bone: Sensitivity to Tissue Anisotropy and Mechanical Behavior." Journal of the Mechanical Behavior of Biomedical Materials.

Average Loading Slope

Loading Slope is a measure of stiffness. It is a measure of bone matrix hardness and the ability of bone to resist plastic deformation.

- Granke, M., A. Coulmier, S. Uppuganti, J. A. Gaddy, M. D. Does and J. S. Nyman (2014). "Insights into Reference Point Indentation Involving Human Cortical Bone: Sensitivity to Tissue Anisotropy and Mechanical Behavior." Journal of the Mechanical Behavior of Biomedical Materials.

- Granke, M., A. J. Makowski, S. Uppuganti, M. D. Does and J. S. Nyman (2015). "Identifying novel clinical surrogates to assess human bone fracture toughness." Journal of Bone and Mineral Research: n/a-n/a.

Plasticity / Work

Average Energy Dissipated

Energy Dissipation is a measure of plasticity and can quantify unrecovered deformation. For example, when you press your finger into a plastic wrap hard enough, it leaves an imprint. In this example, the pressure of your finger has exceeded the elastic limit of the material and it is permanently deformed. In a similar way, the test probe will permanently deform the bone. The energy dissipated during an indentation is quantified by measuring the area under the force-displacement curve, though the mechanism of energy dissipation cannot be known. In general it quantifies a mechanism of reversible energy storage that is active during RPI measurements, reducing the formation of microcracks that typically dissipate a large amount of energy.

- Setters, A. and I. Jasiuk (2014). "Towards a standardized reference point indentation testing procedure." Journal of the Mechanical Behavior of Biomedical Materials 34(0): 57-65.

- Granke, M., A. Coulmier, S. Uppuganti, J. A. Gaddy, M. D. Does and J. S. Nyman (2014). "Insights into Reference Point Indentation Involving Human Cortical Bone: Sensitivity to Tissue Anisotropy and Mechanical Behavior." Journal of the Mechanical Behavior of Biomedical Materials.

- Katsamenis, O. L., T. Jenkins and P. J. Thurner (2015). "Toughness and damage susceptibility in human cortical bone is proportional to mechanical inhomogeneity at the osteonal-level." Bone(0)